MICROGRAVURE™

Thin, Stable, Uniform Reverse Gravure Coating Method

US Patents D355,669 & D346,397

FACT: The world’s largest battery separator manufacturer in Japan developed their coating technology using our MICROGRAVURE™ technology, and they continue to manufacturer their separators using only our technology

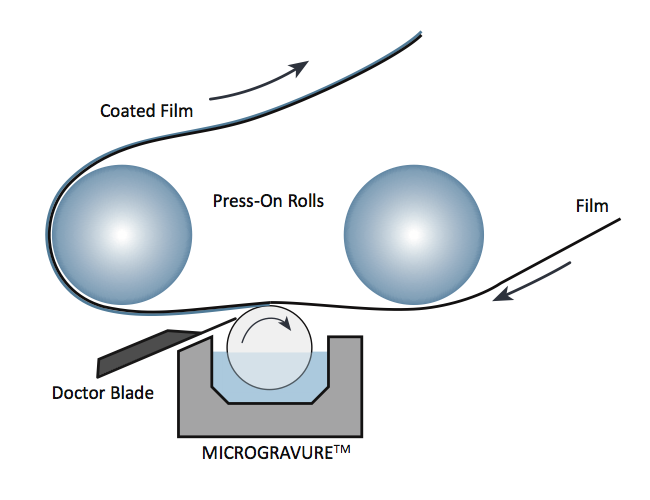

What is MICROGRAVURE™?

A smaller diameter gravure roll engraved with patterns or cells to provide a specific coating volume. It is used in a reverse kiss coating method in which the roll is partially submerged in a pan of solution. The roll rotates in the opposite direction of the web, and the cells pick up the coating solution. The flexible doctor blade lightly smoothes off the excess and the precisely measured solution in the cells is then transfered to the web.

Why is MICROGRAVURE™ better than regular gravure?

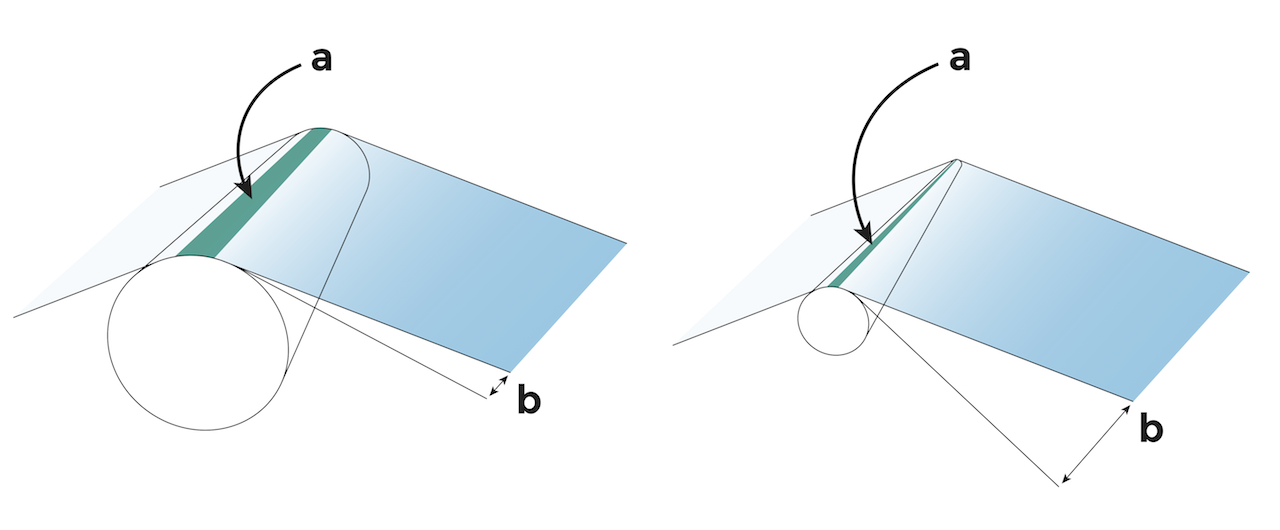

- The smaller diameter provides a much smaller contact area (a), which allows for an exceptionally stable bead of solution that is critical for thin, uniform and glossy coatings

- The larger web-to-roller distance (b) minimizes streaks and offers cleaner lines

- No backing roll - means no creasing, smaller contact area, prevents spillover to the other side

- Can coat low viscosity solutions

- Lightweight cylinder means faster & easier changeover

- Reverse coating creates shearing which results in a smoother surface

| Regular Gravure | MICROGRAVURE™ |

|---|---|

| Large contact area (a) and small web-to-roller (b) distance | Small contact area (a) and larger web-to-roller distance (b) |

| Unstable bead of solution | Very stable bead of solution |

| Unstable coating | Exceptionally stable, glossy and uniform coating |

What experts say about this? Read more...

What can MICROGRAVURE™ do?

- Offers exceptional uniformity: ±2% tolerance

- Coats 0.5 to 80 microns wet, as thin as 5 nanometers dry

- Coats low viscosity solutions (0-1000 cP), both aqueous and solvent based

- Coats on thin substrates such as PET, PC, PP, aluminum, copper, stainless steel, paper and fabric

Where can you try MICROGRAVURE™?

MIRWEC's Contract Coating facility in Bloomington, Indiana offers coating trials using many different size MICROGRAVURE™.

- Our smallest R2R lab coater, Mini-Labo™ is equipped with MICROGRAVURE™

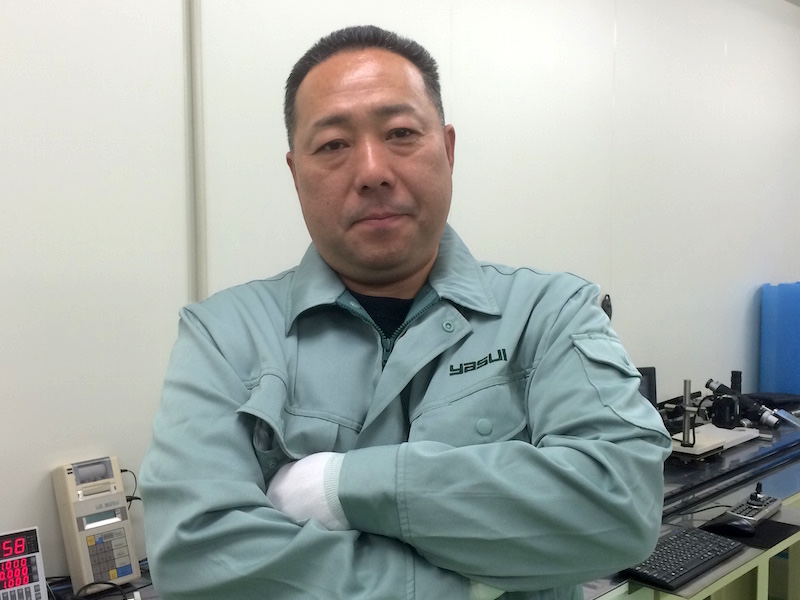

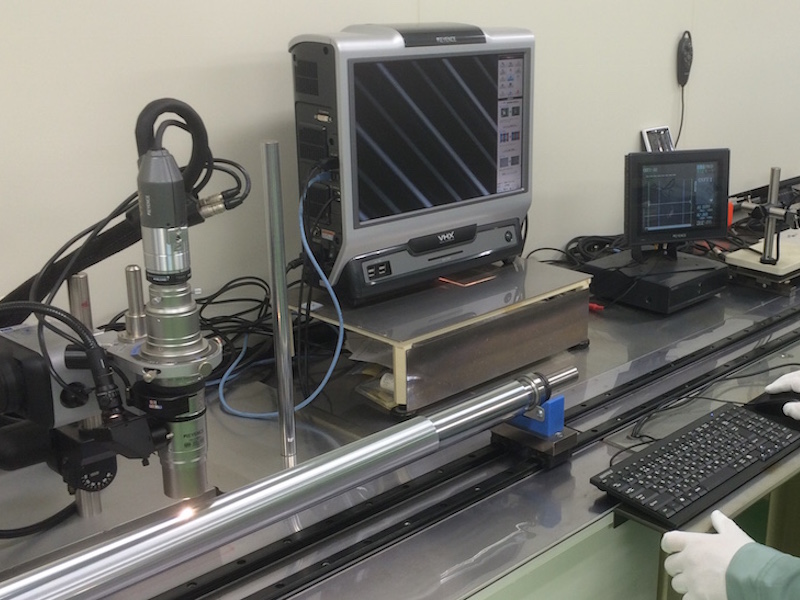

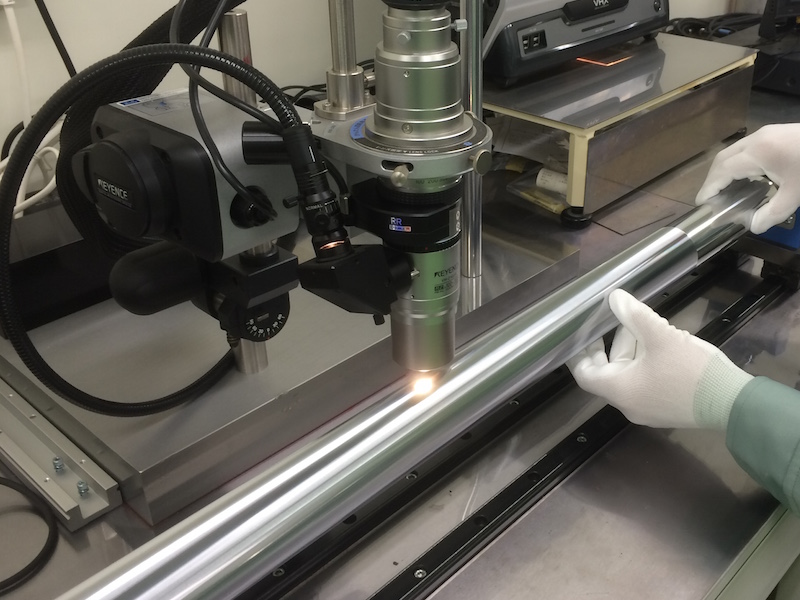

Yasui Seiki Workmanship

Yasui Seiki MICROGRAVURE™ rolls are made-to-order custom rolls. Each roll goes through numerous manual finishing procedures that are our trade secrets. Along with the finishing procedures, all meticulous physical, mechanical and chemical tests are manually done with extreme care by our Master MICROGRAVURE™ Engineer. Only Yasui Seiki can deliver full functionality of one-of-a-kind MICROGRAVURE™.

Application Examples

Yasui Seiki MICROGRAVURE™ is the method of choice in Japan for the coating process of multiple layers in LCD displays as well as touch screen components. Our technology is predominantly used in essential electronics, such as smartphones, tablets, computer monitors and other LCD displays. 95% of the smartphones sold in the US contain at least one layer coated by one of our MICROGRAVURE™ coating machines. MICROGRAVURE™ application is also rapidly growing in the Li-ion battery, solar cell, and window film industries.

OPTICAL

- 0.005 to 0.015 μm AR/ LR coating on optical films

- 2 to 3 μm hard coating on optical films

- 14 μm photoresist coating for hologram application

BATTERIES

- 0.5 to 1 μm carbon nanotube coating on aluminum foils

- 2 to 4 μm insulation coating on porous separator films

- 2 to 5 μm reflective coating for solar cells

PRINTED ELECTRONICS

- 0.3 to 2 μm silicone coating on PET

- 1 to 3 μm photoresist coating on PET

See Applications for more application examples.

MICROGRAVURE™ Roll Mesh Volume

| Mesh | Reference Thickness (Wet μm) |

| R25 | 50 - 80 |

| R30 | 30 - 45 |

| R36 | 28 - 43 |

| R38 | 25 - 40 |

| R45 | 28 - 43 |

| R50 | 25 - 35 |

| R55 | 20 - 30 |

| R60 | 21 - 31 |

| R65 | 13 - 22 |

| R70 | 16 - 25 |

| R75 | 20 - 30 |

| R80 | 12 - 20 |

| R85 | 13 - 22 |

| R90 | 8 - 16 |

| R95 | 7 - 15 |

| R100 | 6 - 14 |

| R110 | 6 - 13 |

| R120 | 5 - 11 |

| R150 | 4 - 9 |

| R180 | 3 - 8 |

| R200 | 2 - 5 |

| R230 | 1.5 - 3.5 |

| R250 | 1 - 2 |

| R400 | Currently in testing phase |